What advancements are shaping the current steel industry? Recent innovations have transformed raw materials into specialized, customizable solutions, reaching new heights in quality, efficiency, and versatility. Let’s explore key techniques, benefits, and real-world applications.

Key Techniques in Modern Fabrication

Modern methods allow those typing ‘steel sheets near me’ online to access top-quality, customized solutions:

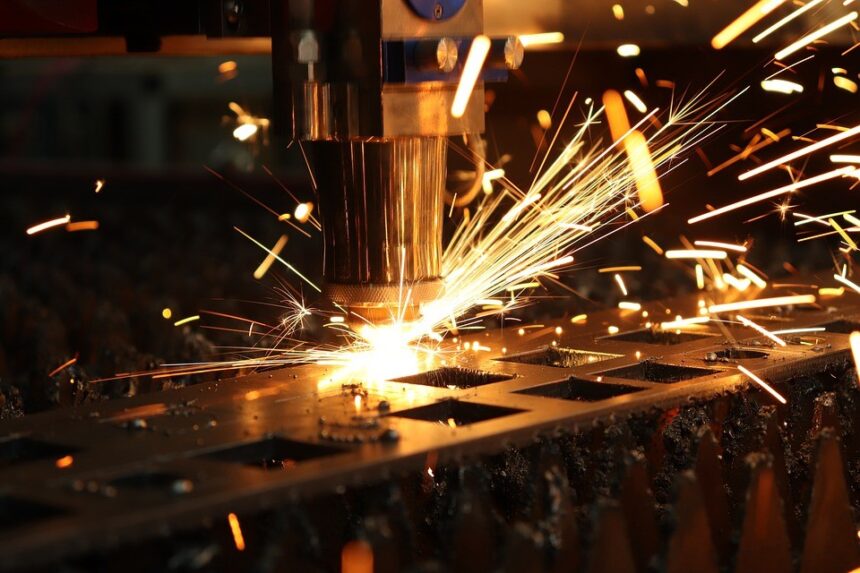

- Cutting and Shaping: Tools like lasers and plasma technology achieve precise shapes with minimal waste.

- Welding and Joining: MIG and TIG methods create strong, lasting bonds between components.

- Forming and Bending: Hydraulic presses and CNC bending enable intricate shaping, adding flexibility to designs.

- Surface Finishing: Powder coating, galvanizing, and polishing extend durability and enhance appearance.

These advanced techniques ensure products meet unique structural needs and achieve high durability standards. Innovations continue to expand the possibilities in metalwork, pushing the boundaries of what can be achieved in design and functionality.

Benefits of Advanced Fabrication Techniques

With advanced techniques, clients benefit from solutions precisely aligned with unique project specifications, adding significant versatility.

Key benefits include:

- Customization: Advanced methods enable highly customized solutions that are crafted to meet specific project requirements.

- Efficiency and Speed: Automation and CNC technology streamline production, reducing lead times. This has revolutionized production speed and cost-effectiveness.

- Enhanced Durability: High-quality welding, shaping, and finishing methods create durable parts suited for demanding environments, contributing to project longevity.

- Sustainability: Precision techniques minimize waste, promoting sustainable practices. Sustainable steel production supports high industry standards while enhancing green initiatives in manufacturing and infrastructure development.

With the adoption of advanced methods, industries are better equipped to meet evolving market demands with solutions that combine precision, durability, and environmental responsibility. These methods allow companies to stay competitive by delivering superior products while minimizing resource consumption and waste.

Use of Fabricated Steel in Various Industries

From construction to energy, such fabricated metal supports critical functions across multiple sectors:

- Construction and Infrastructure: Metal forms the backbone of buildings, bridges, and structural supports, meeting rigorous load-bearing standards.

- Automotive and Transportation: In vehicles and aerospace, fabricated parts enhance frames, railway structures, and more. Metal’s durability ensures reliable, safe transport components.

- Energy and Utilities: This material is essential in power plants, oil rigs, and wind turbines, which provide the resilience needed in harsh environments.

- Manufacturing and Machinery: The flexibility of custom parts supports efficient production, allowing manufacturers to build tools and machinery that boost operational performance.

As demands for sustainable and resilient solutions increase, steel continues to play a pivotal role in enabling safe, efficient, and forward-thinking designs. By adapting to evolving industry standards and incorporating advanced techniques, such fabricated metalwork drives progress in sectors critical to economic growth and societal development, ensuring durability, adaptability, and sustainability in every application.

How Fabrication Companies Support Industry Growth

Metal fabrication companies nowadays are performing as key players in enhancing productivity, quality, and innovation within multiple sectors:

- Meeting Specific Industry Demands: Companies provide modified solutions that meet the precise standards and requirements of various sectors, ensuring optimal performance.

- Cost Savings through Efficiency: By supplying installation-ready, accurately crafted components, these companies help industries reduce labor and material costs on-site, boosting overall efficiency.

- Enhanced Product Quality and Longevity: Custom-made parts often surpass standard quality measures, offering industries durable, reliable, and high-performance metal products.

- Driving Innovation across Sectors: These fabrication companies promote competitiveness across multiple industries by offering access to the latest techniques and technologies that ensure unmatched precision and quality.

By continuously adapting to new technologies and industry standards, fabrication companies play an essential role in driving industrial advancement. Their expertise in delivering precise, high-quality solutions modified for specific needs elevates individual projects and contributes to broader industry growth.

The Role of Skilled Labor in Advanced Techniques

Despite the increase in automation, skilled labor remains crucial in the industry. Technicians and operators with expertise in CNC programming, welding, and metalworking are essential for ensuring that machines and systems run smoothly and produce quality components.

- Skilled workers bring deep knowledge and an understanding of metallurgy, ensuring that each project meets exact requirements.

- With advanced training programs and certifications, the industry continues to develop a workforce that can harness the full potential of modern equipment while maintaining high safety and quality standards.

- Skilled laborers also play a key role in adapting to customization demands, as many projects require unique, hands-on adjustments to fulfill precise specifications.

Sustainability and Eco-Friendly Initiatives in Metalwork

The industry is adopting sustainable measures to lessen its ecological footprint as environmental responsibility gains importance.

- Eco-friendly materials and recycling initiatives are now commonly implemented to reduce waste, especially in larger-scale projects. Companies are also investing in energy-efficient technologies to reduce emissions and overall energy consumption during the production process.

- Many plants adopt closed-loop systems to recycle leftover materials back into production, minimizing waste and promoting circular economy principles. Moreover, advanced software systems optimize material usage and planning, ensuring that resources are used more efficiently with less impact on the environment.

These efforts not only align with global sustainability goals but also meet the rising demand from clients and industries that prioritize green initiatives in their operations and supply chains.

Quality Assurance and Compliance in Modern Metalwork

With stringent industry regulations and high-performance standards, quality assurance and compliance are critical in metalwork.

- Companies now implement rigorous quality control protocols that involve both automated and manual inspection techniques to ensure every part meets specific standards. Non-destructive testing (NDT) methods, such as ultrasonic, magnetic particle, and radiographic testing, are frequently used to verify the integrity of components without damaging them.

- Compliance with industry standards, like ISO 9001 for quality management and ISO 14001 for environmental management, assures clients of consistent, high-quality results and sustainable practices.

Through these measures, the industry builds trust with clients and stakeholders by guaranteeing that every component not only meets but often exceeds the required quality and safety standards.

Innovative metalworking has transformed industries, providing durable and customized solutions that support growth and efficiency. Those exploring on the internet by typing ‘steel sheets near me’ benefit from sustainable, cost-effective materials that meet the unique needs of modern industry. As companies adopt new technology, they drive advancements in quality, reliability, and industry standards, cementing steel’s role as a vital resource in the current economy.