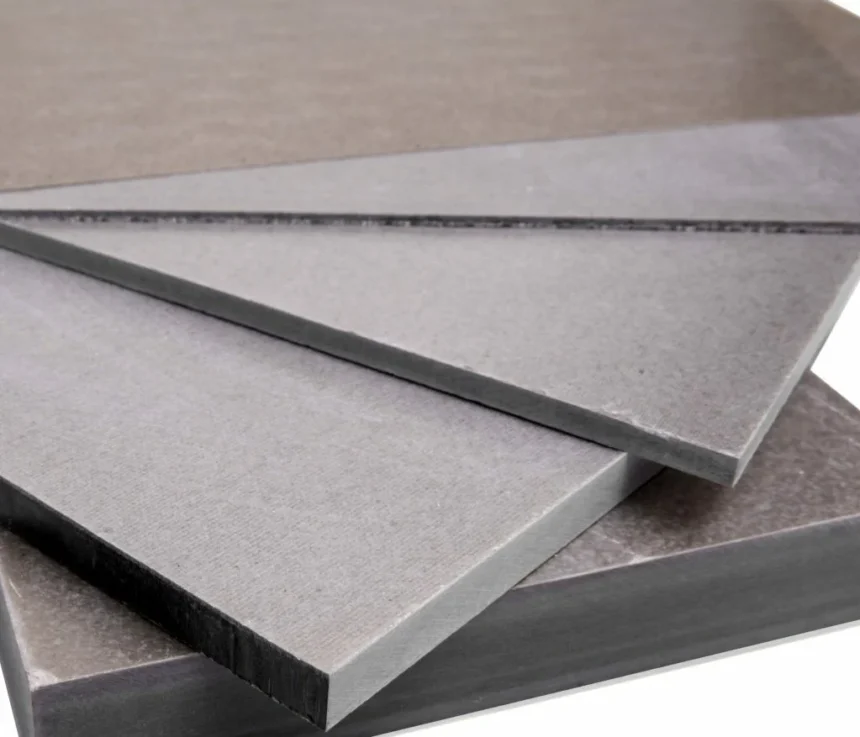

As facility managers, procurement specialists, and construction professionals looking for the best insulation materials, one natural solution stands out: mica sheets. However, with different grades and specifications available, the challenge lies in selecting the right mica sheet grade to meet your specific thermal insulation needs.

This comprehensive guide reveals the various mica sheet grades, providing invaluable insights to help you make informed decisions that align with your thermal insulation requirements, performance expectations, and long-term cost considerations.

Mica Sheet Detailed Grade Differences

Mica sheets are available in various grades, each with unique properties tailored to specific thermal insulation applications. Understanding the nuances between these grades is crucial in ensuring optimal performance and longevity. Here’s a closer look at the primary mica sheet grades:

- Phlogopite Mica: Known for its exceptional heat resistance and flexibility, phlogopite mica is an ideal choice for high-temperature applications. This grade can withstand temperatures up to 1,000°C (1,832°F) without compromising its insulating properties, making it suitable for furnaces, kilns, and other extreme environments.

- Muscovite Mica: Renowned for its superior dielectric strength and resistance to electrical arcing, muscovite mica is the go-to choice for electrical insulation applications. However, its thermal insulation properties make it a viable option for applications where temperatures reach up to 700°C (1,292°F).

- Biotite Mica: Valued for its resistance to chemical and moisture degradation, biotite mica offers excellent thermal insulation capabilities in corrosive environments. This grade is often used in industrial processes involving harsh chemicals or high humidity levels.

Mica Sheet Selection Criteria:

When choosing the right mica sheet grade for your thermal insulation needs, several critical factors must be considered:

- Operating Temperature Range: Evaluate the maximum and minimum temperatures your insulation will be exposed to, and select a mica sheet grade that can withstand these conditions without degradation.

- Environmental Conditions: Consider factors such as humidity, chemical exposure, and potential for vibration or mechanical stress, as these can impact the performance and durability of different mica sheet grades.

- Application Requirements: Assess the specific application, whether it’s a furnace, boiler, electrical component, or HVAC system, and choose a mica sheet grade that meets the industry standards and regulations for that application.

- Long-term Performance: While initial cost is a consideration, prioritize long-term performance and reliability by selecting a mica sheet grade that provides consistent insulation over an extended period, reducing maintenance and replacement costs.

Performance Data and Cost-Benefit Analysis

To make an informed decision, it’s crucial to understand the performance characteristics and cost-benefit implications of each mica sheet grade. Here’s a glimpse of the comparative data:

| Mica Sheet Grade | Thermal Conductivity (W/m·K) | Max Temperature Resistance (°C) | Mechanical Strength |

| Phlogopite Mica | 0.2 – 0.3 | Up to 1200 | High |

| Muscovite Mica | 0.3 – 0.4 | Up to 1000 | Moderate |

| Vermiculite Mica | 0.12 – 0.18 | Up to 1100 | Low to Moderate |

By analyzing this data, you can weigh the upfront investment against the long-term benefits of improved energy efficiency, reduced maintenance costs, and extended lifespan, ultimately leading to a more cost-effective and sustainable solution.

Long-term Reliability and Environmental Impact

Choosing the right mica sheet grade not only ensures optimal thermal insulation but also contributes to long-term reliability and sustainability. High-quality mica sheets can provide consistent insulation performance for decades, reducing the need for frequent replacements and minimizing potential downtime.

Furthermore, selecting a mica sheet grade that enhances energy efficiency can significantly reduce your facility’s carbon footprint, aligning with environmental and sustainability goals. By minimizing heat loss and improving thermal insulation, you can reduce energy consumption and associated greenhouse gas emissions, contributing to a greener future.

Compliance and Safety

In high-temperature applications, compliance with industry standards and safety regulations is of utmost importance. Different mica sheet grades may be subject to specific guidelines and certifications based on their intended use and operating conditions.

By working closely with reputable mica manufacturers and consulting industry experts, you can ensure that the chosen mica sheet grade meets all relevant safety standards and regulatory requirements, mitigating potential risks and liabilities associated with thermal insulation failures.

Conclusion

In the ever-evolving landscape of thermal insulation, choosing the right mica sheet grade is a critical decision that can have far-reaching implications for your operations, cost-effectiveness, and environmental impact.

By carefully considering the detailed grade differences, selection criteria, performance data, and cost-benefit analyses, you can select a mica sheet solution that not only meets your immediate thermal insulation needs but also contributes to long-term reliability, sustainability, and compliance with industry standards.

Embrace the power of nature’s remarkable material and harness the full potential of mica sheets by investing in the appropriate grade for your thermal insulation requirements. With the right mica sheet grade, you can ensure optimal performance, energy efficiency, and peace of mind in even the most demanding high-temperature applications.