Stepper motors are like the muscles of machines such as 3D printers, CNC mills, and laser engravers. They work behind the scenes, taking instructions from the computer and turning them into precise movements. Imagine them as the hands that move your machine along the X, Y, and Z axes.

If you’re delving into the world of DIY 3D printers, choosing the right stepper motors is crucial. Without them, your machine won’t budge an inch. To simplify this process, we’ve crafted a detailed guide covering everything you need to know about stepper motors.

This article will walk you through the basics of stepper motors: what they are, how they function, their role in 3D printing and CNC machining, the different types available, and essential installation tips. So, let’s dive into the fundamentals.

How does a stepper motor work?

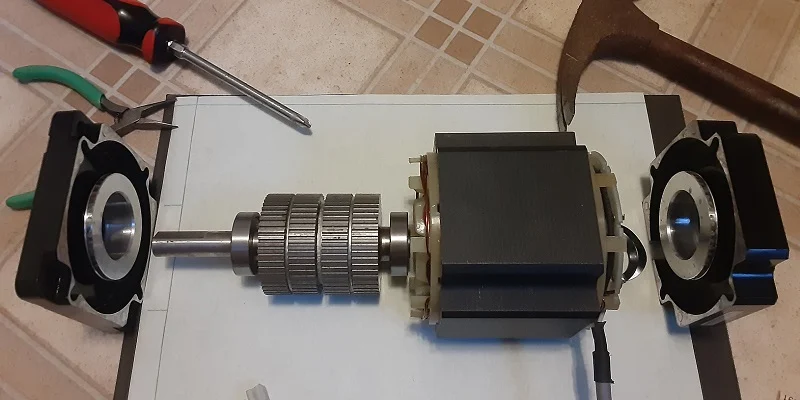

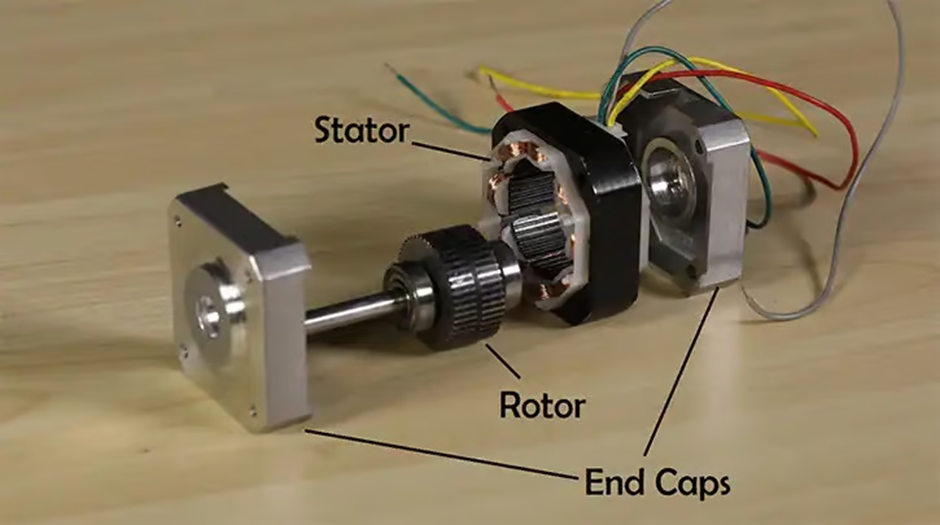

Stepper Rotor: Image Source: Digi-Key

A stepper motor is a special kind of electric motor that operates differently from typical motors. Unlike regular motors that turn continuously in a circular motion, stepper motors move in discrete steps or increments. This unique ability to move precisely in steps makes them perfect for applications where accuracy is crucial, like in 3D printers.

The inner workings of a stepper motor include coils that are energized when electricity flows through them. These coils are controlled using electrical pulses, allowing for precise control over the motor’s movement. Essentially, stepper motors can start and stop at specific positions as needed, making them ideal for tasks requiring exact positioning.

In contrast to gasoline-powered engines that rely on the combustion of fuel, stepper motors rely solely on electricity to function. This distinction highlights the versatility and efficiency of electric motors in various technological applications.

Where can stepper motors be found?

Let’s start by diving into where you’ll spot stepper motors in your machines. In the realm of 3D printers and desktop CNC machines, you’ll find them playing crucial roles on the X-, Y-, and Z-axes. These motors, often aided by belts or Screws, translate rotational energy into linear movements for precise positioning.

For the X and Y axes, each typically has its own motor. They use mechanisms like belts or screws to convert rotational motion into the linear motion needed for precise movement. The Z-axis, responsible for carrying the weight of the toolhead, usually has one or two stepper motors, typically employing screws for this vertical movement.

In case the motor is not converting rotational motion into linear motion due to inefficient support by belts or screws, you can consider PEEK Screws to ensure the effective working of motion mechanisms. New and high-quality screws can help motors work more efficiently.

In 3D printers, there’s an additional stepper motor dedicated to filament extrusion. This motor, connected to a system with a spring, pulley, and gear, drives the filament’s movement. Conversely, CNC machines forgo stepper motors for spindle control due to their need for higher torque and speed, relying instead on integrated electric motors.

Understanding where stepper motors fit into these machines sets the stage for delving into how they operate.

What does NEMA stand for?

Different sets of stepper motors: Image Source: Pololu

Have you ever wondered what NEMA means? When it comes to DIY 3D printers, CNC machines, or stepper motors, the term “NEMA” often pops up. While many use NEMA and stepper motor interchangeably, there’s a bit more to it.

NEMA stands for the National Electrical Manufacturers Association, the largest trade group for electrical equipment makers in the US. This association has established the standard for stepper motors globally, leading to the interchangeable use of these terms. This standardization ensures that all motors labeled as NEMA adhere to the same specifications in terms of dimensions, capacity, torque, voltage input, and more.

However, it’s crucial to note that while other electrical components like traditional AC motors can also meet NEMA standards, they aren’t necessarily stepper motors. Therefore, caution is necessary when discussing “NEMA” in the context of stepper motors.

What Exactly is Torque and How Does it Affect Stepper Motors?

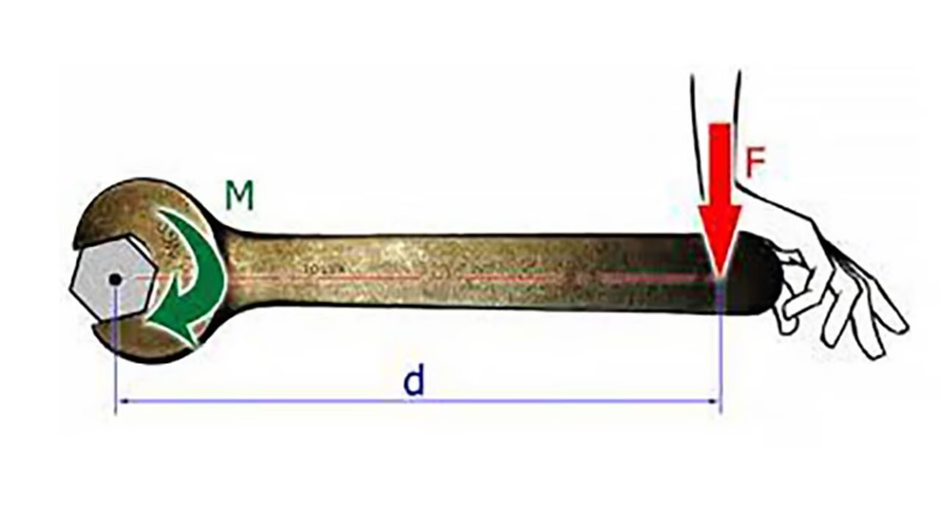

Calculating torque: Image Source:MDME

When you dive into stepper motors, you’ll encounter the term “torque” frequently. It’s a crucial specification that dictates what a motor can handle in terms of movement. In simple math, torque equals force multiplied by distance. Imagine torque as the rotational counterpart of force in linear motion. Essentially, it’s the power behind circular movement. The higher the torque, the more weight a motor can effectively manipulate in a circular path.

Expressed in units of force and distance, torque for stepper motors is typically denoted in N-cm (Newton x centimeter) or Oz-in (ounce x inch), as per the formula shared earlier. Understanding torque is pivotal in selecting the right stepper motor for your application, ensuring it can handle the required load and deliver the desired performance.

What are the different types of NEMA?

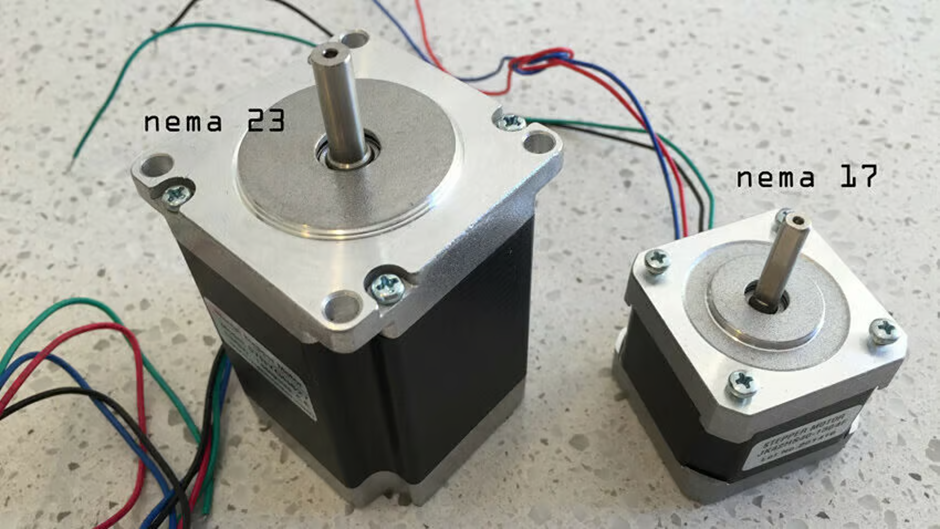

Different types of NEMA: Image Source: Satoms

NEMA stepper motors come in two main types: NEMA 17 and NEMA 23, named after their respective faceplate sizes of 1.7″ x 1.7″ and 2.3″ x 2.3″. The size difference directly impacts their torque, determined by internal transmission components like rotors and gear sets.

NEMA 17 motors typically deliver around 50 N-cm of torque, suitable for many applications. In contrast, NEMA 23 motors offer higher torque, ranging from 100 to 125 N-cm, crucial for heavier materials like aluminum.

Within each type, variations exist. For instance, all NEMA 23 motors are high torque, surpassing even the most powerful NEMA 17 motor. This distinction is vital; for lower torque needs, NEMA 17 is preferable due to its availability.

NEMA 17 further branches into three common types based on length and torque:

1. Pancake Motors: Compact and low torque, about 2 cm long with 13 N-cm.

2. Standard Length: The most prevalent, 4 cm long with 50 N-cm.

3. High Torque: Longer at 6 cm but offers 65 N-cm, albeit still less than NEMA 23.

While more NEMA 17 variations exist, they might not be as widely accessible as these three.

What Are the Alternative Motor Options for CNC Systems?

Different variations of motor: Image Source: amazon.com

In certain situations, the standard options may not meet your specific requirements. Thankfully, there are additional choices worth exploring:

1. Geared Steppers: These motors, often built from modified NEMA 17s, employ gearboxes to boost either speed or torque. Increasing torque reduces speed, and vice versa. They serve well across various applications. For instance, if you need higher torque than a NEMA 17 can offer but lack space for a NEMA 23, a geared NEMA 17 could be a viable solution due to its smaller size.

2. Brushless Motors with Encoders: A newer CNC movement variant, these systems with brushless DC motors are notably faster (and sometimes stronger) than typical steppers. However, they’re pricier and more complex to set up due to their advanced noise reduction, vibration control, and enhanced torque and precision capabilities.

3. Servo Motors: While not as precise as steppers and incapable of continuous rotation, servo motors are ideal for small actuating components like couplers or filament switching mechanisms. They’re typically secondary motors, best suited for tasks with lower torque demands, such as button pressing.

Drivers act as the vital link between your computer and the stepper motor in your printer. Essentially, they translate software commands into electric pulses, orchestrating the precise movements of the motor according to instructions.

When choosing drivers, it’s crucial to consider the compatibility with your stepper motor’s reference. Not all drivers seamlessly work with every motor reference. Additionally, assessing whether the drivers operate silently can be advantageous, as they may contribute to the noise you hear during machine operation.

Drivers significantly influence the stepper motor’s accuracy by controlling its movement through micro-steps. These micro-steps, determined by both your printer’s firmware and the drivers used, refer to the number of electric pulses needed for the motor to complete one step. Typically, micro-steps are in multiples of 8 (8, 16, 32, 64, 128, etc.), with an optimal range between 32 and 64 to balance resolution and communication efficiency.

Understanding Printer Drivers and Stepper Motor Precision

Drivers act as the vital link between your computer and the stepper motor in your printer. Essentially, they translate software commands into electric pulses, orchestrating the precise movements of the motor according to instructions. These electronic components connect to the mainboard of the printer, with the stepper motors then linked to the drivers.

When choosing drivers, it’s crucial to consider the compatibility with your stepper motor’s reference. Not all drivers seamlessly work with every motor reference. Additionally, assessing whether the drivers operate silently can be advantageous, as they may contribute to the noise you hear during machine operation.

Drivers significantly influence the stepper motor’s accuracy by controlling its movement through micro-steps. These micro-steps, determined by both your printer’s firmware and the drivers used, refer to the number of electric pulses needed for the motor to complete one step. Typically, micro-steps are in multiples of 8 (8, 16, 32, 64, 128, etc.), with an optimal range between 32 and 64 to balance resolution and communication efficiency.

Installation of the stepper motor:

Installing stepper motors is typically easy due to standardized connectors. Just plug the motor into the right slot on the control board, and you’re set. However, there are important precautions:

1. Safety First: Never install or unplug a motor while the printer is on. Turn it off and unplug it to avoid shocks, component damage, or fires.

2. Powering: Never unplug a powered stepper motor. Follow step one to prevent damaging the motor or control board.

3. Current Adjustment: Ensure correct current supply to motors using potentiometers or printer software. Too little or too much current can cause issues.

4. Wiring Check: If the motor doesn’t work, check for crossed or inverted wires using a multimeter. Correct wiring ensures proper motor function.

5. Post-Installation: If the motor behaves oddly, stop, power off, and check wiring and compatibility. This prevents potential hazards like fires or component damage.

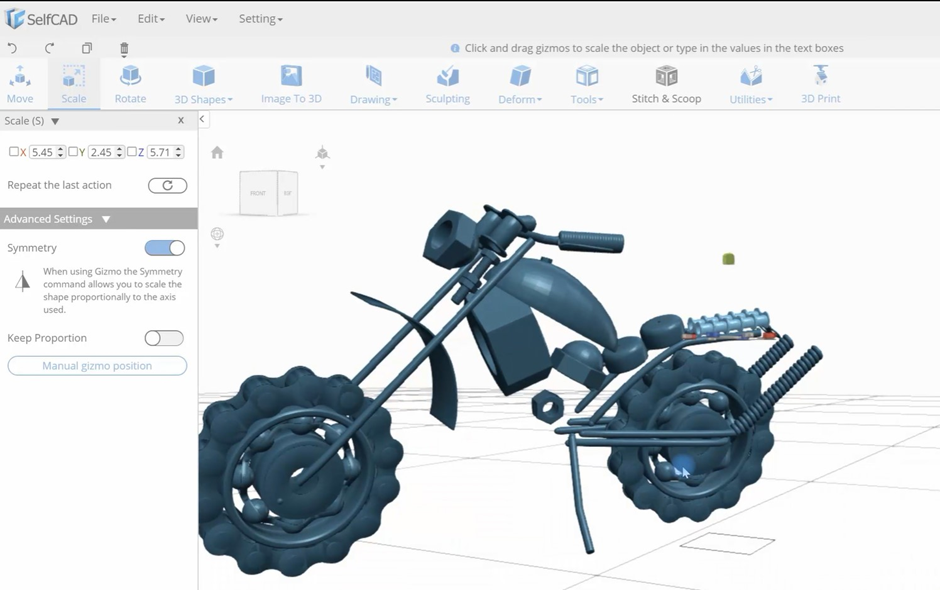

SelfCAD: Budget-friendly 3D Modeling Software

SelfCAD: Budget-friendly 3D Modeling Software: Image Source: selfcad.com

SelfCAD stands out as a budget-friendly 3D design solution suitable for all skill levels. Whether you’re a business professional, freelancer, or student delving into 3D design, SelfCAD fits the bill. It streamlines 3D model creation, preparing them swiftly for 3D printing, animation, or rendering, cutting down time compared to traditional CAD tools. Perfect for novices, its user interface is intuitive, facilitating easy tool understanding. Tools are logically grouped for quick access, enhancing productivity. Notable features include a range of 3D shape generators for foundational designs and robust 3D sculpting capabilities for organic shapes. SelfCAD’s simplicity extends to tasks like image-to-3D conversion and direct mesh manipulation, ensuring seamless workflow without switching between programs.

Conclusion:

In conclusion, stepper motors play a crucial role in the functionality of 3D printers, providing precise control over movement. Understanding their operation, installation safety, and troubleshooting ensures optimal performance and reliability in 3D printing processes.