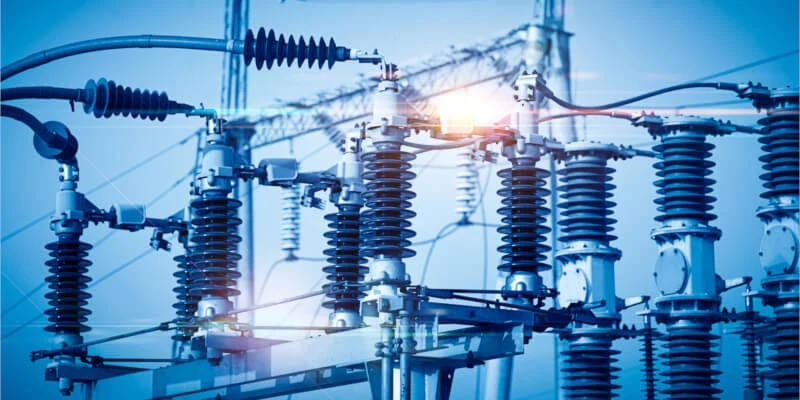

Transformers are the unsung heroes of our modern electrical world. They’re everywhere, silently ensuring that power flows smoothly and safely. But what keeps these powerful devices in check? That’s where insulation materials come in.

Insulation materials are critical in electrical transformers, maintaining their efficiency and longevity. From traditional paper and oil to modern synthetics, the choice of insulation can significantly impact a transformer’s performance.

Role of Various Insulation Materials in Transformers

Insulation materials play critical roles in transformers, ensuring efficiency, safety, and peak performance. But what are these magical materials, and why are they important? We’ll explore, understand, and appreciate the value of different insulation materials transformers utilize.

Transformer Oil

Transformer oil functions primarily as both an insulator and coolant. Its job is to prevent circuits from short-circuiting and maintain dielectric strength. It helps distribute heat and shields conducting components from corrosion. Unique concoctions of paraffin, naphthenes, aromatics, and olefins from transformer oil. Fault detection in oil-immersed transformers is usually done through a Buchholz relay test.

Electrical Grade Paper (Kraft Paper)

Kraft paper is economical in insulation and has a high dielectric strength. It’s often used for winding insulation and condenser core bushings.

Pressboard

In electrical, mechanical, and thermal capacities, pressboard originates from cellulose, specifically softwood pulp. It can be molded into various shapes, such as angle rings and caps.

Wood-Based Laminates

These laminates, composed of selected veneers from diversified timber sources, add necessary mechanical strength. You can find it in coil clamping rings, cores, yokes, and supports.

These materials contribute to a transformer’s reliability, stability, and safety. Proper selection and maintenance form the backbone of robust electrical systems. Remember that various factors influence the optimal choice: transformer type, location, and operating conditions.

Every day, insulation materials prove their worth. They shield us from electrical mishaps, enabling our gadgets to work seamlessly. Can you imagine a world without them?

Various Insulation Materials in Transformers

Transformers need reliable insulation materials to function effectively and safely. In this segment, we’ll examine numerous insulation materials used in transformers, focusing on their unique qualities and utilities.

Insulating Oil

Oil proves invaluable as a mainstay in transformer insulation. This substance engineered for optimal dielectric strength provides both cooling and insulation, crucial to arresting internal arcing. Oils such as mineral oil, ester oil, and silicone oil—all referenced in this professionally written report—are commonly used. As this study points out, regular maintenance of insulating oils contributes significantly to the transformer’s lifespan.

Insulating Paper

Insulating paper is essential in transformer insulation systems. It is manufactured from pure cellulose, which boasts high electrical and mechanical strength. As this article outlines, insulating paper is generally used as paper or Kraft paper, offering excellent capacity for withstanding mechanical stress.

Insulating Tape

Insulating tape, often constructed from polyimide or polyester, provides additional protection and binding for leads and connections. A valuable reference by electrician blogs, like TheSpruce, offers further insights into this material’s role in preventing current leakage and electrical failures.

Pressboard

Pressboard, a high-density insulating paper, is critical for mechanical support and electric insulation. According to this ResearchGate source, pressboards are highly valued in transformer designs for their exceptional stability and durability.

Wood-Based Laminates

Wood-based laminates also offer a prominent solution for insulation in transformers. Seamless layers of compressed cellulose fiber provide a natural insulation product with high dielectric strength and superior thermal management. This guideline from the Nuclear Regulatory Commission gives an authoritative glimpse into their application.

To sum up, all these insulation materials, each with distinct properties, contribute to the durability and efficiency of transformers. The choice of insulation material depends heavily on factors such as transformer type, operating conditions, and location, a topic that we’ll discuss in the next portion of this ongoing primer.

Conclusion

We’ve journeyed through the world of transformer insulation materials, right? From transformer oil to wood-based laminates, we’ve seen how each material plays its part in keeping our transformers efficient and long-lasting. The choice of insulation isn’t a one-size-fits-all scenario. Factors like transformer type, operating conditions, and location come into play. We’ve also learned that properly maintaining these materials is as crucial as the selection process. So here’s our parting thought: let’s consider the power of the right insulation. It’s the unsung hero that keeps our electrical systems robust and reliable. Let’s give it the attention it deserves. After all, a well-insulated transformer is a happy transformer. And a happy transformer makes for a happy, efficient, safe electrical system. That’s a win-win situation for everyone, isn’t it?