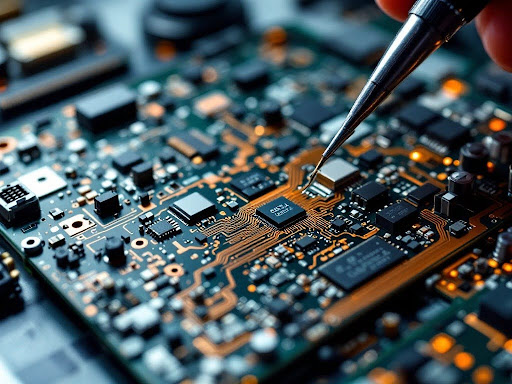

Printed Circuit Boards (PCBs) form the backbone of modern electronics, enabling everything from basic functionality to advanced performance in a wide range of applications. Certain industries benefit significantly from professional PCB layout services due to their unique requirements for precision, durability, and compliance. Here, we dive deeper into the ten key industries that benefit most from these services and explore their specific needs.

1. Consumer Electronics

Consumer electronics is perhaps the most widespread application of PCBs. The industry thrives on producing compact, high-performance devices that require complex PCB layouts.

Key Challenges and Benefits:

- Miniaturization: As consumer devices like smartphones and smartwatches become more compact, PCB designers need to fit numerous components into smaller spaces. Professional PCB layout services use advanced design tools and techniques like High-Density Interconnect (HDI) to achieve this.

- High Performance: Devices like gaming consoles and VR headsets demand optimized layouts to handle high-speed signals while minimizing electromagnetic interference (EMI).

- Mass Production: Consumer electronics require PCBs that are not only efficient but also cost-effective for large-scale production.

Applications:

- Smartphones with multi-layer PCBs that handle processors, memory, and communication modules.

- Smart TVs and home entertainment systems with PCBs designed for enhanced audio and video performance.

- Wearable devices like fitness trackers that require rigid-flex PCBs for flexibility and reliability.

2. Automotive Industry

Modern vehicles are equipped with a multitude of electronic systems, ranging from safety features to infotainment systems. Professional PCB layout services are critical in ensuring these systems perform flawlessly in demanding environments.

Key Challenges and Benefits:

- Environmental Resilience: Automotive PCBs must endure high temperatures, vibrations, and humidity. Specialized layouts improve durability under these conditions.

- Safety Compliance: Systems like airbags and advanced driver-assistance systems (ADAS) rely on PCBs designed to meet strict automotive safety standards such as ISO 26262.

- Power Distribution: Electric vehicles (EVs) require PCBs capable of managing high currents in applications like battery management systems (BMS) and charging modules.

Applications:

- Engine control units (ECUs) with PCBs optimized for rapid signal processing.

- Electric vehicle charging stations with PCBs designed for high-power applications.

- Advanced infotainment systems integrating navigation, connectivity, and multimedia features.

3. Aerospace and Defense

The aerospace and defense industries demand the highest levels of precision and reliability in electronic systems, often operating in extreme conditions. PCB layout services tailored to this sector ensure uncompromising performance.

Key Challenges and Benefits:

- Extreme Conditions: Aerospace PCBs must withstand high altitudes, radiation, and rapid pressure changes. Professional designers ensure these PCBs function reliably under such conditions.

- Stringent Standards: Defense PCBs often adhere to MIL-PRF-31032 and other military specifications that govern quality and performance.

- Custom Solutions: Many aerospace systems require highly customized PCB layouts for mission-critical applications.

Applications:

- Radar systems and communication modules used in military aircraft and satellites.

- Navigation and guidance systems requiring low-latency signal processing.

- Unmanned aerial vehicles (UAVs) with lightweight, power-efficient PCBs.

4. Medical Devices

The medical industry relies on electronic devices for critical diagnostics, monitoring, and treatment. Professional PCB layout services ensure these devices are reliable, safe, and efficient.

Key Challenges and Benefits:

- Life-Saving Reliability: Medical PCBs must operate without failure, as any malfunction could have serious consequences.

- Compact Designs: Devices like pacemakers and hearing aids require miniaturized PCBs with rigid-flex or microvia designs.

- Compliance with Standards: Medical PCBs must meet strict standards, such as ISO 13485, ensuring safety and quality.

Applications:

- Portable diagnostic devices like blood glucose monitors with compact and durable PCB designs.

- Imaging systems like MRI machines that require multi-layer PCBs for high-speed data processing.

- Wearable medical devices for real-time health monitoring.

5. Telecommunications

The telecommunications industry demands PCBs capable of managing high-speed data and ensuring reliable connectivity in global networks.

Key Challenges and Benefits:

- Signal Integrity: Telecom PCBs must minimize signal loss and electromagnetic interference to maintain high-quality communication.

- Thermal Management: Devices like base stations and servers generate significant heat, requiring PCBs with efficient heat dissipation designs.

- Scalability: Telecom networks evolve rapidly, and PCBs need to support future upgrades.

Applications:

- 5G infrastructure, including base stations and routers, utilizing advanced PCB layouts.

- Fiber optic communication systems with high-frequency PCBs for efficient data transfer.

- Network switches and servers with multi-layer PCBs for high data throughput.

6. Industrial Automation

Industrial automation systems rely on PCBs to control machinery, monitor processes, and manage power. Professional layout services ensure these PCBs meet the industry’s rigorous demands.

Key Challenges and Benefits:

- Durability: Industrial environments often expose PCBs to dust, moisture, and mechanical stress. Professional layouts enhance durability and reliability.

- Customization: Many industrial systems require PCBs tailored to specific equipment configurations and functions.

- Power Efficiency: Proper power distribution in PCB layouts ensures machinery operates at peak efficiency.

Applications:

- Robotic control systems using PCBs for motor drivers and sensors.

- Programmable Logic Controllers (PLCs) with custom PCB designs for precise automation control.

- Power management units in manufacturing plants.

7. Renewable Energy

The renewable energy sector demands robust PCBs for managing power systems in solar, wind, and other energy technologies.

Key Challenges and Benefits:

- High Power Handling: Renewable energy PCBs must handle large power loads with minimal loss.

- Outdoor Durability: Solar inverters and wind turbine control systems require PCBs that perform reliably in outdoor environments.

- Efficiency Optimization: Professional layouts improve energy conversion efficiency.

Applications:

- Solar inverters with PCBs for efficient DC-to-AC power conversion.

- Wind turbine controllers using rugged PCBs to manage operations.

- Battery management systems in energy storage solutions.

8. IoT (Internet of Things) Devices

IoT devices are revolutionizing industries by enabling connected systems for monitoring, control, and automation. PCB layout services play a crucial role in ensuring these devices function seamlessly.

Key Challenges and Benefits:

- Compactness: IoT devices often require small, lightweight PCBs with integrated wireless modules.

- Power Efficiency: Optimized layouts extend the battery life of IoT devices, especially in portable applications.

- Connectivity Integration: Professional services ensure PCBs support technologies like Wi-Fi, Bluetooth, and Zigbee.

Applications:

- Smart home devices like thermostats, security cameras, and lighting systems.

- Industrial IoT sensors for monitoring machinery and processes.

- Wearable IoT devices for fitness tracking and health monitoring.

9. Computers and Data Storage

The computing industry depends on high-performance PCBs to drive processing, storage, and data transfer systems. Professional PCB layout services are critical to meeting these requirements.

Key Challenges and Benefits:

- High-Speed Design: PCBs must support fast data transmission for processors and memory systems.

- Thermal Management: Proper heat dissipation ensures reliable operation in high-performance computing.

- Scalability: PCBs need to be designed for future technology upgrades.

Applications:

- Motherboards with advanced layouts for gaming and professional computing.

- SSDs and storage arrays with optimized PCBs for fast data access.

- Data center servers with multi-layer PCBs for high-speed networking.

10. Semiconductor Manufacturing Equipment

Semiconductor manufacturing equipment requires precise and reliable PCBs to support the production of advanced chips. Professional layout services ensure these PCBs meet exacting standards.

Key Challenges and Benefits:

- Precision Design: Semiconductor PCBs must handle micro-level signals with high accuracy.

- Continuous Operation: Equipment often runs 24/7, necessitating durable PCB layouts.

- Signal Integrity: Proper layouts ensure minimal signal distortion in complex processes.

Applications:

- Lithography machines with PCBs for precise imaging and etching.

- Wafer testing equipment using high-frequency PCBs for accuracy.

- Chip packaging systems require robust PCB designs.

Conclusion

Professional PCB layout services are indispensable for industries that demand precision, durability, and compliance. By addressing unique challenges and delivering optimized designs, these services empower innovation across sectors, from consumer electronics to aerospace. As technology continues to evolve, the role of expert PCB design will remain critical in driving advancements and ensuring reliable performance in a diverse range of applications.